Continuous Improvement Through Investigation

Investigation Management

A reaction to an incident, or a sustainable improvement process?

Leaders in asset intensive industries believe there is always room for improvement. Whether the trigger is an incident or near miss, knowledge of chronic issues or high cost areas of operations, Investigation Management plays a significant role.

The methods of Investigation Management range from a simple 5-Whys analysis to a more detailed and complex cause and effect approach. While most reliability engineering groups vary the technique to suit the problem, analyses generally fail due to cumbersome systems. Failure can also occur when Investigation Management knowledge is not passed on to other work sites within the company structure.

It is critical to track the implementation and the effect of a recommendation to prove the recurring problem has been eliminated or to indicate that further actions or analysis must be taken.

Nexus Global’s end-to-end approach to Investigation Management improves processes and procedures to prevent human error and equipment failure occurrence.

You may also be interested in:

Investigation Optimizer

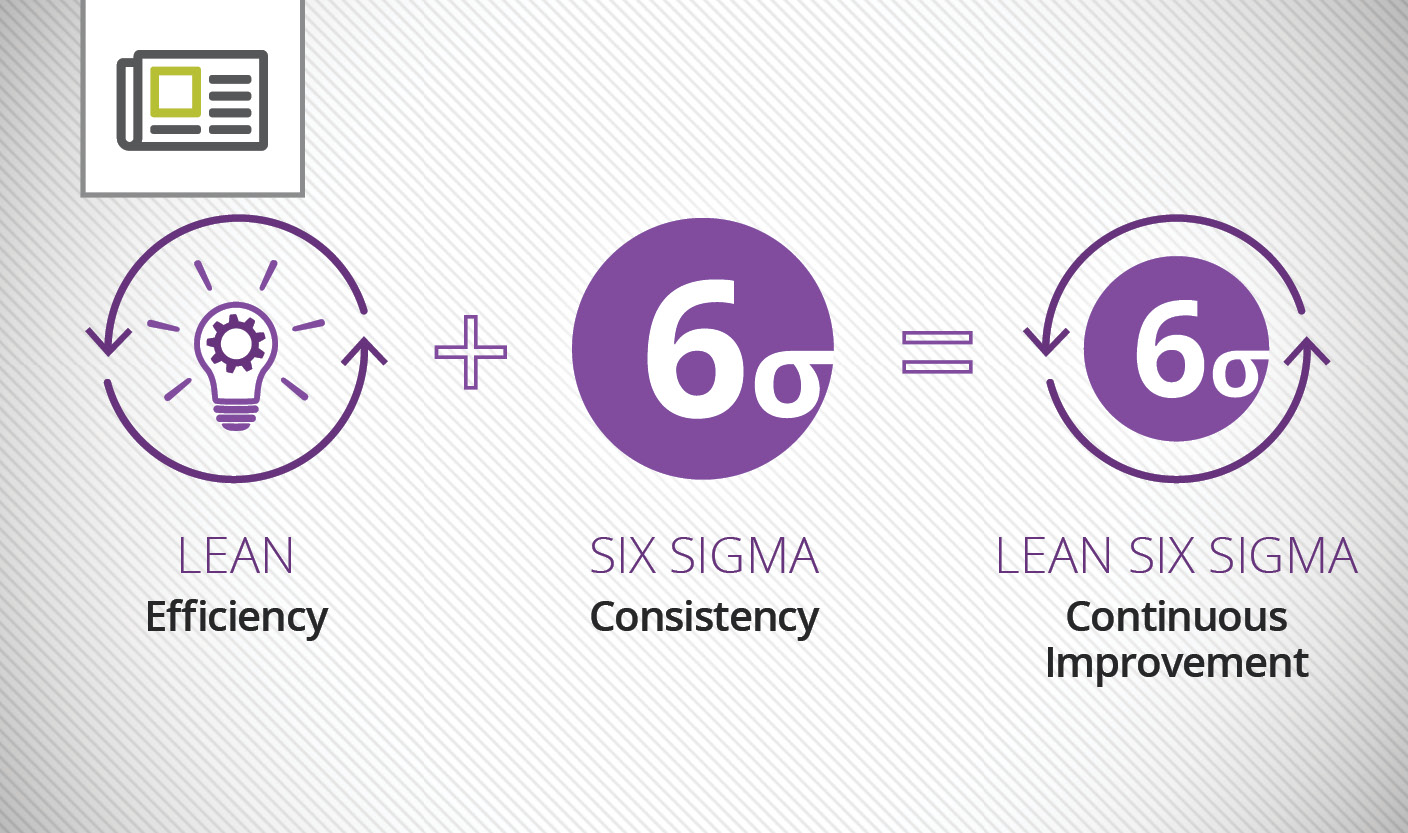

Featuring a Lean Six Sigma DMAIC process, Investigation Optimizer guides you and your team through systematic problem solving to standardize root cause thinking and reduce variability.

Arab Gateway Port and Transshipment Hub APM Training

Nexus Global was awarded a long-term training contract to support a major Omani seaboard shipping port as they continue efforts towards achieving world-class operational standards. Operating since November 1998 and recognized globally as a leading transshipment hub, this world-class...

Asset Performance Management | More Than Just Implementing EAM

Defining APM: Gartner defines Asset Performance Management (APM) as encompassing the capabilities of data capture and cleansing, integration, visualization, and analytics/digitalization tied together for the explicit purpose of improving the reliability and availability of physical...

DMAIC RCA: A Proven Approach to Reliability

What is DMAIC RCA? DMAIC, pronounced “duh-may-ik," is a data-driven approach to problem-solving designed to identify and improve existing process inefficiencies with unknown causes. As one of the most important tools in any continuous improvement...

Best Practices - Asset Management, ISO 55000, Industry 4.0

On this episode, Larry talks withPilar Valderrama, Asset Management Technology Manager for Stork-Flour, about her mission to bring Asset Management and ISO 55000 to Latin America. Pilar shares why implementing Asset Management programs with ISO 55000 standards and embracing Industry 4.0...

Tying Risk/Investigations/Root Cause Analysis (RCA) Together

More than 50% of the process industry is still operating with paper or file-based maintenance systems and people dependent processes for Root Cause Analysis (RCA). In today's environment, innovation is no longer an option. To stay relevant with performance and ride out the retiring...

© 2023 Nexus Global. All rights reserved. | Privacy Policy

.png?width=1408&height=833&name=BLOG_APAPA_APM%20Terminals_Featured%20Image%20(1408%20%C3%97%20833%20px).png)